Rapid Rail Bridge Repair

Engineered Rigging’s Rapid Rail Bridge Replacement System enables railroads and their maintenance contractors to remove and replace a railroad bridge span in a single day. In addition to substantial time savings, the system also provides a safer method for bridge replacement than traditional barge crane, 2-crane picks or hydraulic cylinder / sliding approaches. The Rapid Rail Bridge Replacement System is proudly engineered and manufactured with domestic materials in the U.S.A.

Unique Design

Engineered Rigging’s 250 or 500+ ton Rapid Rail Bridge Replacement System is comprised of four mechanically engaged lift columns (two at each end), a horizontal lift girder connecting the columns, drivable trolleys that guide the bridge span along the lift girder, and transport carts to carry away removed spans and deliver replacements.

Top-of-Rails Design: installs on top of the rails, rather than under, eliminating the need for extensive below-rail modifications to adjacent sections

Enclosed Lift Girder: doubles as a safe passageway, enabling crews to cross from one side of the bridge to the other once the span is removed

Modularity: eases handling, shipping and setup

Easy Transport & Rapid Assembly

By setting up this bridge replacement system on a nearby spur, rail service is not interrupted during assembly.

- Assembles in three to four shifts

- Ships to rail spur on four to five legal flatbed trailers

- Requires no wide load or heavy load permits

Safe, Fast Operation

Railroads can use the Rapid Rail Bridge Replacement System to safely exchange a bridge span in just one day, significantly less time than hydraulic cylinder methods. Depending on the number of spans, railroads can safely and efficiently complete an entire bridge replacement in days rather than months.

Mechanically Engaged Lifting: no cable drums or strands that can fail or hydraulics that leak

Self-Locking Lift Columns: perfectly synchronized lifting and positive mechanical engagement 100% of the time

Power Failsafe: lift columns that maintain stability during power outage

Remote Operation: lifting and transport controlled from a safe distance

Standard Configuration

The Rapid Rail Bridge Replacement System features a 250 – 500+ ton lifting capacity that is capable of replacing most railroad bridge spans. Engineered Rigging can customize the system to meet unique customer requirements. Components include:

- Four 30-foot lift columns

- Two lift column connector beams

- One central span box girder

- Two adjustable ladders

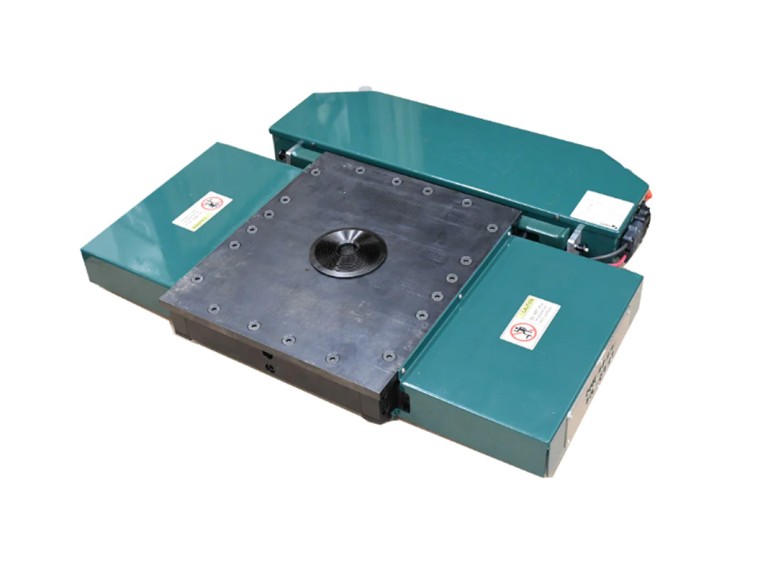

- Two trolleys and drive systems

- Lift system transport carts

- Bridge section transport carts

- Synchronized control system with power unit

Compliance

Engineered Rigging’s Rapid Rail Bridge Replacement System complies with the applicable sections of the following standards:

- AISC Manual of Steel Construction, 9th Ed. and 13th Ed.

- ASCE 7-10, Minimum Design Loads for Buildings and Other Structures

- AWS D1.1, Structural Welding Code

- 29 CFR 1926, OSHA Construction Industry Regulations